Buyer always confused, “I have compared the materials of your two factories, and they are similar, but why, your prices are higher than others?”

This is what I want to discuss with you today – Our Technique.

It’s not just through words, and pictures show the difference.

Process of the gun body

There are many kinds of gun body machining processes, which involve CNC lathe, CNC machining center, drilling machine, etc. Our high-end spray guns are produced by machining centers, set up through multiple molds, all process in one, thus ensuring accuracy and productivity. The most superior feature is that the CNC machining center adds the function of milling. On another way, regular spray gun factories, still with CNC group as the primary, labor and time costs increase, while the accuracy of the product will not be better than us.

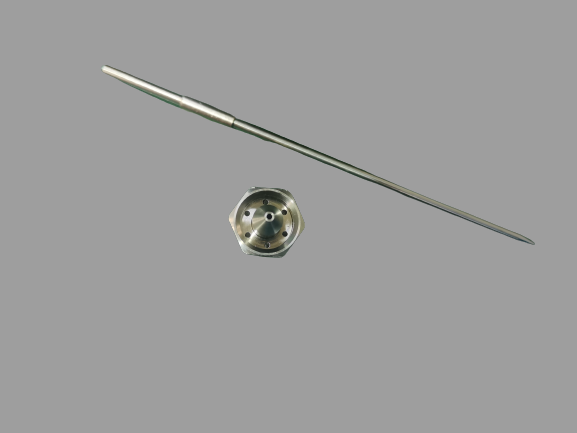

Process of nozzle, needle& air cap

The key to a good or better spray gun is the craftsmanship of its needle, nozzle, and air cap. It guarantees the performance and lifespan of the spray gun. We have machined these core three sets by ourselves.

Firstly, the machining of the needle. Adopted one-to-one strategy means each needle corresponds to a matching nozzle. The taper of the needle/ tip is most vital during the processing. Each batch of the machined needle will be inspected randomly, though assemble into the spray gun, watching the distances between the nozzle and needle when pulling the trigger. The tolerance is under 0.3mm-0.5mm, can be passed.

Then, the nozzle/tip of the spray gun. We strictly follow the standards set, precision machining from design, blank, rough machining, drilling, finishing. The inspection method is the same as the needle.

Last but not least, the craftsmanship of the air cap. It doesn’t seem very easy than others. As we all know, the working principle of the spray gun compressed the air, mixing with paint, combined in the head of the spray gun, and ejected into the tip, last, spraying the ideal pattern. The horn holes, which are in the side of the air cap, are influenced by the spray sharpness. Central holes, supplementary holes as well. Usually, the hole sizes are between 0.5mm-1.5mm. Tiny sizes are very difficult for machining. But we do it as usual. First of all, rough finishing by CNC machining to polishing the shape. Then through a particular CNC machining center ONLY for holes, using high precision tools for processing. See how it works below.

As a high-quality spray gun manufacturer, we have a professional technical team for machining. They are many experienced and outstanding guys.

These two craftsmanship show passion and professionalism, as we are a high-quality manufacturer. We want to offer the best spray guns in China. Next article, I will introduce someone behind the spray gun. I cannot wait to see it!

Welcome to contact us with questions or comments!