– We said, ” Our products are of good quality. We are a high-quality spray gun manufacturer!”

– The buyer said,” All Chinese suppliers will say that and who will tell our quality is BAD.”

Nothing wrong with that!!

Today, what I want to explain to you, why our spray guns are better than others? Why are they more expensive than our peers? What makes them cost more?

So let’s start with the raw materials first.

- Gun Body

Most spray guns use die-cast aluminum for bodies in the current market. Such as car refinishing spray guns, e.g., EFC series, we use forged aluminum, which costs more money than die-cast and is complex in the process. It will have a much better sense of touch, no gaps inside, good performance, and wear resistance than die-cast aluminum. For a comparison of die-cast aluminum and forged aluminum, see this link below. On the other hand, die-cast aluminum also has many advantages, like flexible and accepting polished or electroplated finishes, which we use in different models. It is one of the most common raw materials used for bodies and reduces overall costs.

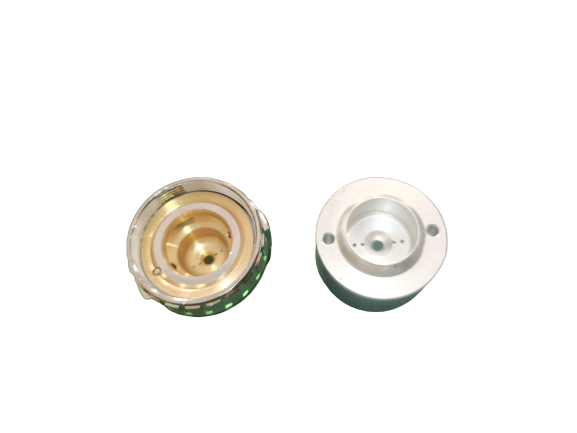

- Nozzle, Needle& Air Cap

This three-piece set is the most crucial accessory in the gun, and the corresponding craftsmanship is the most complex and essential in ensuring quality. First of all, we use 303 stainless steel for nozzle&needle, which is wear-resistant, corrosion-resistant, and easy to process. However, a few customers request other materials, such as stainless iron, to reduce the cost, in the corrosion performance is not as good as stainless steel. Similarly, there are many kinds of raw materials for air caps. The regular ones are aluminum and copper. We used copper to make the air cap, which is pricey than aluminum but meets our high-end position.

- Sealing Parts

A dozen large and small seals in a spray gun spread out in the feed inlet, air inlet, spray pattern, valve needle, etc. Like a devoted soldier, prevent the air from flowing out of the gun and ensure that the pressure-fed airflow with paint can be wholly ejected from the nozzle without leaking. That’s why the selection of materials for the seals is critical. Polyformaldehyde, PTFE, and rubber are commonly used. Polyformaldehyde is relatively complex and often used in airflow, pattern, and paint flow adjustment for wear and corrosion protection, improving the gun’s lifespan. PTFE is a softer solid material with a smooth surface, low coefficient of friction, and self-lubricating, making it an ideal oil-free lubrication material, often used in valves, components in the gun’s head, reducing maintenance costs and increasing longevity.

- Paint Cup

Aluminum, stainless steel, and plastic are the materials often used in the mainstream market. The end-consumer will decide which one to use depending on their usage habits, the type of paint, and the object’s size being sprayed. So how do you judge a good paint cup of spray gun? Firstly, regardless of the material of the pot, it is their mission not to leak. The threads achieve them. We have added stainless steel joints to the original feed interface for wear resistance to prolong the lifespan. Secondly, they are not easily deformed, whether by dropping or long-term use. The paint cup is thicker and more resistant to fall and likewise costs more.

The materials chapter is almost finished. But this is not the core of what we do. Although Chinese suppliers can buy quality materials, processing and manufacturing is the key to making a high-quality spray gun. There are some technical requirements and a commitment to product excellence involved here.

Next post, I’ll write about our factory’s obsession with craftsmanship and secrets! Feel free to leave your comments, email us with questions, or visit our website and find us.