Hi, as we all know, the most challenging thing to build trust between strangers is especially true for interests. How to make buyers feel that we are an honest and professional factory to make spray guns? How to highlight our good quality and not just talk about it?

First, let me introduce our company. We are a medium-sized factory with only about 30 people and only produce spray guns, but every factory employee loves our products. Each batch of goods, each spray gun from raw materials inspection, assembly, testing, debugging, loading, and the final satisfactory delivery to customers needs everyone’s perfect cooperation. As one of our enterprise spirit, the staff is our real boss. We work together for the manufacture of high-quality Chinese spray guns.

See how we go about it!

Much experienced stuff for precision workshop & assemble line.

- Precision Workshop

The precision workshop is the first step of production, where there are 24 CNC machines, 3 CNC machining centers, and hundreds of sets of molds. From device debugging, installation, and processing to inspecting qualified products, each machine is like our old buddy, helping us process accurate gun bodies, needles, nozzles, air caps, and other accessories.

- Assembly Line

Most of our assembly line are female workers, who carefully and quickly assemble each part. Because of them build a quality barrier for us. Typically, whatever spray gun has at least 50 kinds of accessories, different materials, shapes, a dozen categories of spray guns, they can recognize at a glance and assemble the whole gun within one minute, which significantly increases the production capacity.

Strictly Quality Control

- Raw Materials Control

Our upstream suppliers are large-scale factories with strict raw material testing standards and can provide relevant inspection certificates. In contrast, we will sample 3-5% for each batch of raw materials, measure, weigh and compare with color cards to identify. The incoming material inspectors are familiar with the characteristics and arrival time of raw materials from each upstream factory to respond and update time progress.

- Assembly Control

After the whole spray guns are assembled, we had made the initial product test, the distance of the tips& needles, when held the trigger tightly, also to feel the motivation and the tightness of each adjustment device, this process must be trying one by one.

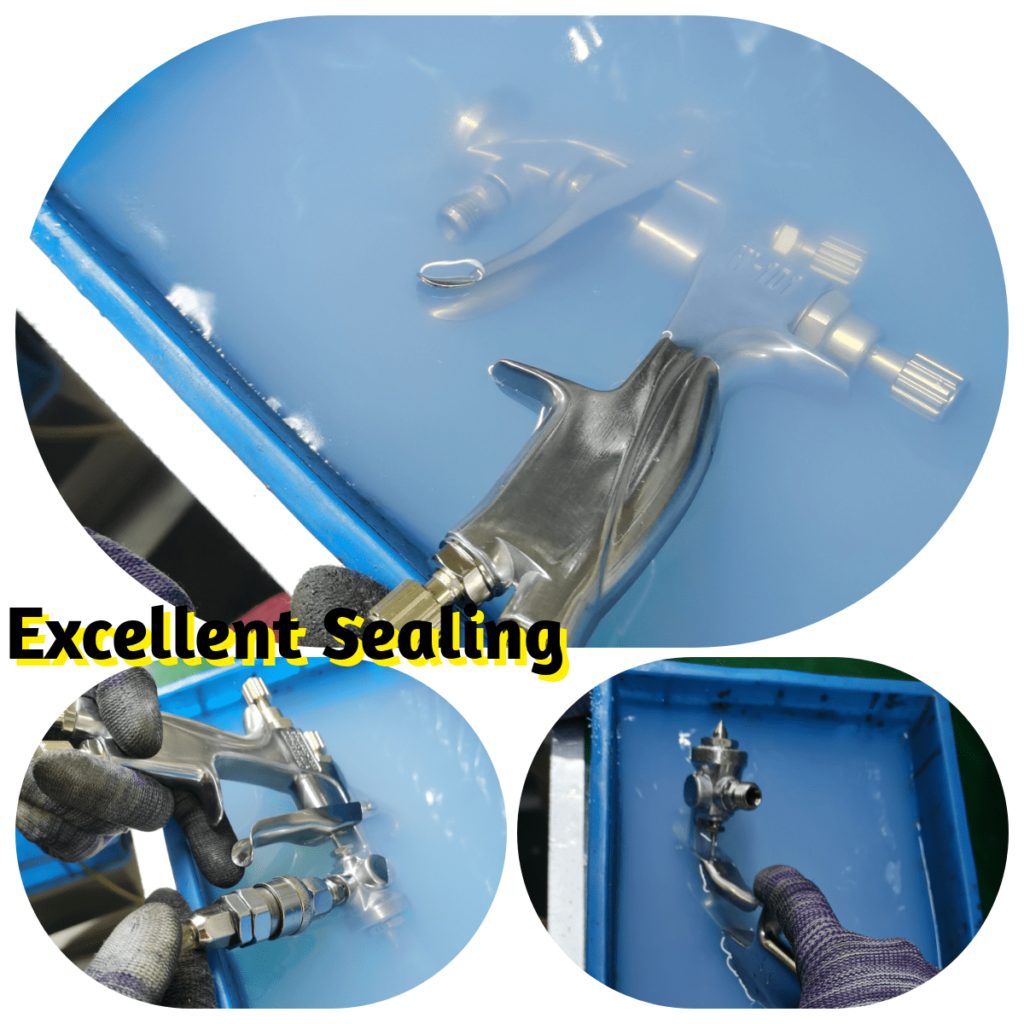

Must be passed 2 product testings

Regular products usually need only one inspection process, while our products must have two methods before leaving the factory. The first one, finishing the assembly, needs to connect the air compressor to the whole gun’s connection and put it into the water to test, such as the air inlet, nozzle, packing parts, no air bubbles are generated to ensure its good sealing. This is often a test that many factories will ignore because it needs a full inspection and ensures no air leakage.

The second test is the most ordinary one, but equally important. The master testing staff has more than 5 years of experience. After connecting the air compressor, close to the spray gun to feel whether the air leakage and by the naked eye identify changes in the spray width, if necessary, with professional tools for debugging. Remember, this is a test of the master’s approach because any mistake will affect the shape of the spray, while the air holes will cause permanent damage.

Well-organized warehouses

We have spare parts warehouse and stocking warehouse, which is the busiest place of the factory every day. The employees of spare parts accept the raw materials inspected and qualified into the warehouse and sort them into different categories. Meanwhile, they will distribute relative components to assembly dep. from more than a thousand kinds of subjects. This job can’t tolerate the slightest mistake. For stocking warehouse is usually accompanied by the sound of forklifts and cargo lifts. Each batch of goods needs to be counted, packed, and safely carried into containers before shipment to the globe.

Every step, every process ensures that orders will be run smoothly. Even whatever issues come, we will be there to solve and handle them at priority. No matter how big or small the order is, every customer is valuable to us.

This is our people and factory if you want to know more, welcome to contact us!