Details make the difference.

Have you ever noticed a difference in the fluid inlet of spray guns? Have your customers ever responded to you that his gun was working fine before and he was taking good care of it? Only recently, it started leaking paint. What happened? After checking for a long time, I found out that the threads on the inlet port were worn and would not seal.

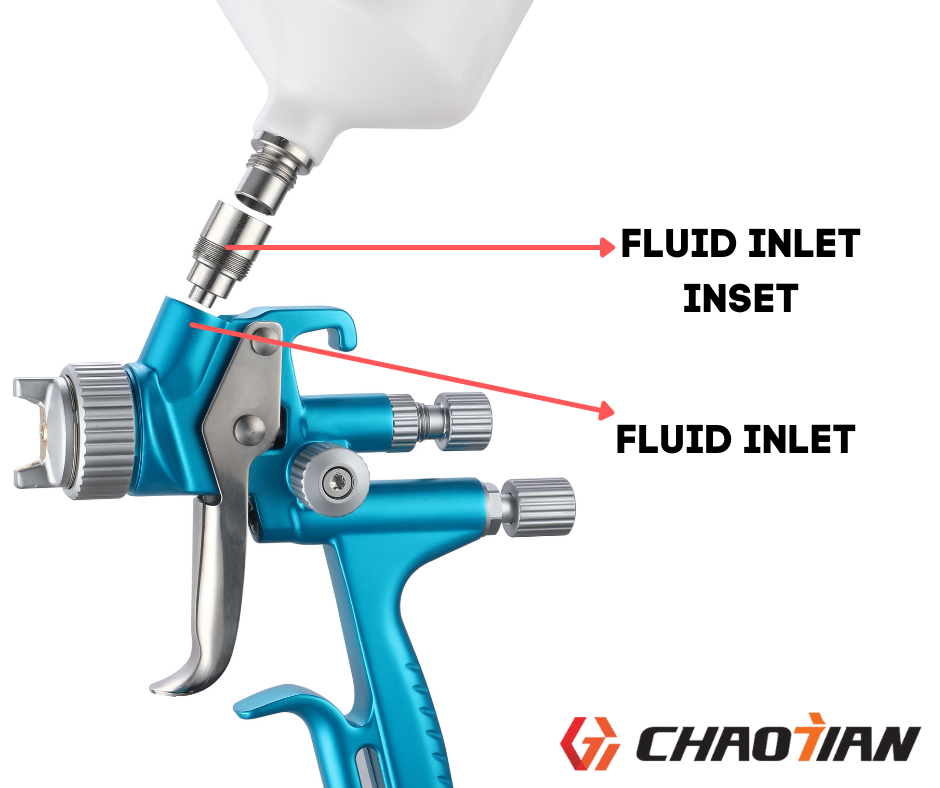

So today, we will talk about the fluid inlet.

There are three types of feed spray guns, the front upper cup, the side cup, and the lower cup, connected with the cup and gun body. But for the front upper container guns, depending on the design of the gun body, there is usually no external fitting but connected by a built-in thread. However, this can easily cause wear and tear.

Why does it wear out quickly?

As we mentioned before, the fluid inlet of this spray gun is directly on the gun body threaded. Due to the gun body is made of aluminum, after a long period of use, the internal threads will be seriously worn, can not play a sealing role, resulting in paint leakage. At this time, the only way to solve the problem is to replace the whole gun body. It will increase the customer’s expense, and at the same time, the quality of the gun will be doubtful.

Our engineers came up with a good solution for this problem by inlaying a stainless steel piece into the feed inlet.

There are some benefits to the stainless steel insert.

- Anti-corrosion and rust prevention

The stainless steel surface is specially treated so that rust will not occur regardless of whether water-based or oil-based paints are used for a long time.

- Resistant to wear and tear

Stainless steel is more solid than aluminum alloy, so it is more resistant to wear and tear, and even with use, it lasts longer.

- Easy to replace

It is an internal insert, and if it’s worn, you only replace this insert, but not the whole gun body. And the replacement procedure is effortless.

How to replace the fluid inlet insert.

- After confirming that the inlet’s stainless steel parts are damaged, remove the paint cup firstly.

- Use a hot air blower to heat the area around the inlet for a while repeatedly. (Because at the factory, to strengthen the stainless steel piece, we apply a special glue around it and then put it into the fluid inlet. This way, the end customer does not fall off when using it.)

- Then it can be removed with a bit of effort using a suitable hexagonal wrench.

- Apply sealant to the new insert and put it into the inlet