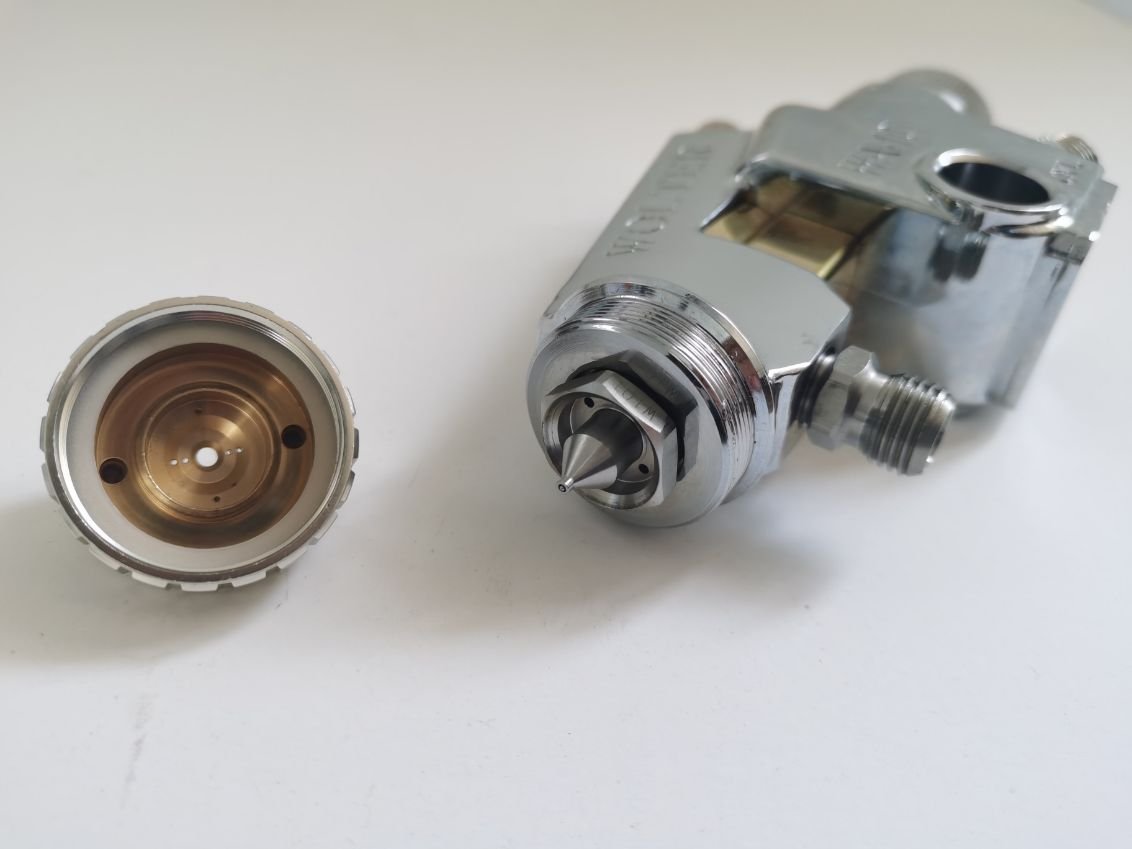

In addition to manual paint spray guns, automatic spray guns are used in a wide range of industrial applications. It has compact size, easy to operate, and saves time and labor. Commonly used in electronics, machinery, glasses, artware, leather, plastic, and other industries of automatic spraying. It can work alone, but also suitable for multiple assembly line work.

Wolter series automatic spray guns made of special stainless steel of needle&nozzle, wear resistance is more than double the ordinary SS316 material, especially available for highly corrosive, high strength, high-frequency spraying equipment.

As everyone knows, a good machine needs fine maintenance despite its good quality. The following are common problems with automatic spray guns. Hope it can help you to know more about your facility.

| PROBLEM | CAUSE | SOLUTION |

| Fluttering | Not enough fluid in the tank | Check and pour |

| Air enters between the fluid nozzle and tapered seat of the gun body or fluid passage | Remove fluid nozzle to clean seat of the gun body or tighten fluid adj. joint section |

| Air is drawn from a fluid needle packing set | Tighten fluid needle packing | |

Crescent | Paint buildup on air cap partially clogs horn holes, air pressure from both horns differs | Remove obstructions from horn holes with an attached tool, but do not use metal objects to clean horn holes |

| Heavy top or bottom (Inclined) | Paint accumulate or damage the fluid nozzle and air cap center | Remove matter. Replace if damaged |

| The fluid nozzle is not properly fitted | Adjusted fluid nozzle, check and clean seat section |

| Split | Paint viscosity too low | Add paint to increase the viscosity |

| Fluid output is too high | Tighten fluid adj. knob to reduce fluid output or turn pattern adj. valve set clockwise | |

| Heave Center | Paint viscosity too high | Add thinner to reduce viscosity |

| Fluid output is too low | Turn fluid adj. valve knob anticlockwise to increase fluid output |

| Spit | The fluid nozzle and fluid needle set are not seated properly | Clean or replace fluid nozzle and fluid needle set |

| The first-stage travel of trigger (when only air discharges) decreases | Replace fluid nozzle and fluid needle set |

| Paint jammed inside air cap set | Clean air cap set | |

| Air leaks from the tip | Dirt, damage, or wear on the piston seal surface | Clean or replace |

| Wear on air valve seat set | Replace the needle spring or air valve spring |

| O ring damage or deformation | Replace | |

| Paint leaks | Fluid nozzle dirty, wear, or damage | Clean or replace parts |

| The fluid needle packing set does not return | Adjust and loose the packing set or paint set |

| Paint clogging | Clogging in the paint nozzle | Clean |

| Insufficient opening/closing of the paint adjusting screw | Set the paint adjustment at a proper position |

For more information, welcome to write us!