HVLP spray gun was known in the painting market for over 30 years since the first compressed- air HVLP spray gun appeared in the late 1980s. Reducing the air pressure, increasing the transfer efficiency, required EU VOCs, but a long operating time is limited for the HVLP Spray gun. Until the year 2000, there were significant advances in atomization technology. The reduction of air pressure and the flow rate has effectively increased the spraying speed. We call this spray gun series APR.

So let’s compare the differences!

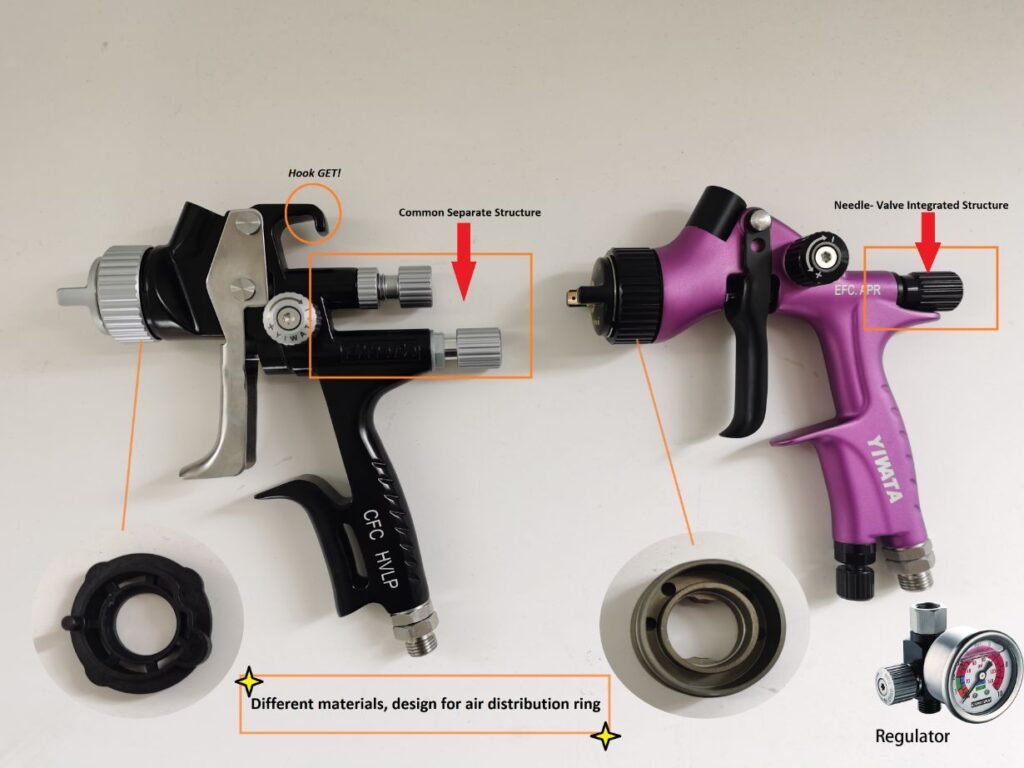

| Item | EFC APR | Regular HVLP |

| Size& Weight | Smart size, lightweight only 444g | Middle size, net weight of the gun is 486g |

| Structure | Adopted patent needle-valve integrated structure | Common separate fluid and air adjustment structure |

| Air distribution ring | Aluminum made, directly installed on the head of the gun, easy to disassemble and no distortion | Plastic made, insert in the head of the gun, 7 holes for distributing the air |

| Hook | No, reduce the weight | Yes, convenient hanging |

| Regulator | Yes, matched special gauge | No, separately purchasing |

In addition to the distinction in appearance and structure, the adoption of different atomization technology is the most important difference between these two guns.

The conventional HVLP spray gun uses a high-volume, low-pressure atomization method, with air consumption of 15 CFM, an inlet pressure of 29-32 PSI, and transfer efficiency over 65%. The APR spray gun has the advantages of the HVLP spray gun but also increases the working speed by more than 10%, and by reducing the pressure and flow rate, the working efficiency is greatly improved.

Regarding atomization pattern, the HVLP spray gun has a fine atomization effect and slender shape, but it has a requirement on the viscosity of the paint, and it needs to add a certain amount of thinner for using high viscosity paint, which is suitable for spraying good liquidity material such as water-based paint. APR Spray gun’s atomization area is reasonably distributed, with an oval and even mist pattern, whether coloring, varnish, silver powder, or water-based, can be used. (Need to pay attention to different paints and conditions on the airflow, volume, spraying distance adaptability adjustment).

Our company focuses on developing APR series products because its performance and coating effect are not very diverse from HVLP, but there is a lot of room for development in terms of improving work efficiency and future trends. We hope that APR technology will be used in large numbers in the spray gun industry and become the most popular type of it for the next 30 years.