The professional buyers focus not only on price but also on quality when purchasing spray guns. The quality of a gun does not mean the exterior materials, and the main thing is the actual atomization effect. This is the most significant difference between a high-end gun and a cheap gun, a professional gun and an amateur gun. So how to understand the atomization effect? What is called a good performance? You can speak from these aspects:

The pattern of the atomization- the most intuitive performance

most people learn about the atomization of a gun and often distinguish it by the pattern size on the surface when operating. This is the most intuitive but not critical point. Because the factory can adjust the size and angles of the corner holes in the air cap during the testing process. Meanwhile, the operator can also change the spraying shape through the pattern and airflow adjustments screws to achieve the desired shape. You can get the patterns you want anyway.

The distribution of the atomization area, the size of the atomized particles, and the stability of the airflow – the core elements of good or bad performance of the atomization effect

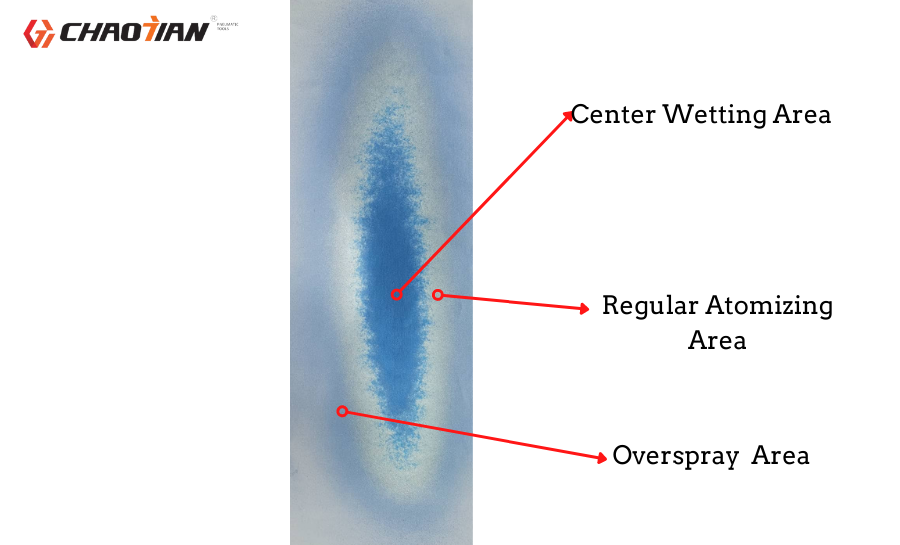

- The distribution of the atomization area: there are three atomized areas of the gun, like the central wetted part, regular atomization part, and the periphery of the overspray part. The overspray area range is limited if you find that the central wetted and typical atomization areas look uniform. So it’s a good atomization effect.

- The size of the atomized particles: the operating principle of the spray gun is to convert the liquid paint into a mist through the airflow, which adheres to the surface of the sprayed object. So if you look close, you can find it will be granular liquid on the surface through uniform spraying and drying to achieve the desired effect. So the particle size will affect the spraying efficiency and the final workpiece. With good atomization, the sprayed particles will be more even.

- The stability of airflow: The strength of airflow is essential for the spray gun, which relates to the structure, seals, and other issues, the most direct impact is the problem of fluttering or air leakage.

Application-the purpose of your spraying for automotive refinish, metal paint, or wood paint. Etc.

- As a tool for spraying – the paint spray gun – there are requirements for the object to be painted. Like, you can’t choose a $20 gun to paint a million-dollar car. It’s ridiculous. So, for automotive spraying, the requirements for atomization are also very different from regular spraying. The most obvious is the distribution of the atomized area and the size of the particles, which is related to the requirements for other paint surfaces. For example, automotive primer requires a thicker paint surface, so the central wetted area needs to be elongated and thickened, and the particles may be more extensive. The paint surface is as thin and uniform as possible for the clearcoat, and the central wetted area cannot be too thick.

- It doesn’t require high atomization requirements for industrial spraying but does demand high transfer efficiency and coverage. Because the paint may have high viscosity or surfaces that do not adhere easily and produce drip hang, customized guns are often necessary to solve these problems.

- So for different spraying purposes and scenarios, you need to pick the right gun to achieve the perfect atomization effect. Never think that all the spraying problems can be solved by one gun all the time.

Many non-professional buyers often focus on price when purchasing spray guns and ignore the performance. Especially for automotive paint spraying, if you use a cheap, unstable atomization gun, it often causes unnecessary trouble for painters and even requires repainting, wasting time and money. This not only creates a bad experience for customers but also damages the company’s reputation.

And as a professional manufacturer of spray guns, sometimes we can not meet the customer’s requirements for price, but reduce the quality of the product, which will make the whole market into a price war, and can not be attentive to a good product. We insisted on good atomization by a good spray gun and hoped to make spraying easy and efficient.