What is the automatic spray gun?

Unlike manual spray guns must be operated by pulling a trigger. The automatic spray gun is usually installed in a fixed position and is controlled by a solenoid valve to achieve automatic spraying. You can use it individually or on assembly lines to reach the bulk production painting.

According to the different situations, applications, machines, and fluids, there are various models in the market. Today we will focus on the WA series, the most common model in the mainstream market. There are two series, WA-101 and WA-200.

WA-101 Industrial automatic painting for Small parts.

WA-101 is designed for mass production on automatic sprayers, reciprocating sprayers, coating robots, and other automated equipment for medium to low viscosity spraying. Thanks to the small nozzle size, the range of 0.8mm to 1.5mm, it’s good at the small object, surface coating, evenly and high efficiency. Also easy to operate with the lightweight gun body.

WA-200 Full-size automatic paint gun for large parts

Automatic spray guns have analogous functions. But for WA-200, it has a broader selection of nozzle sizes from 1.2mm to 3.0mm. Suitable for a variety of applications. They are designed for large parts or objects with thicker paint film.

In addition, almost all of the WA series have the conventional flat-shaped air cap and round air caps, and some have special extended nozzles to meet industrial needs.

Various applications for these two series of guns

Automatic spray guns are mainly applied in industrial fields such as electronics, machinery, glasses, handicrafts, leather, glass, etc. Besides the essential coating spraying, the automatic spray gun can also spray some special coatings, such as polyurethane UV coating, epoxy top coat, multi-component epoxy primer, mold release fluid, rust prevention oil, etc. Save time and cost for your industrial working.

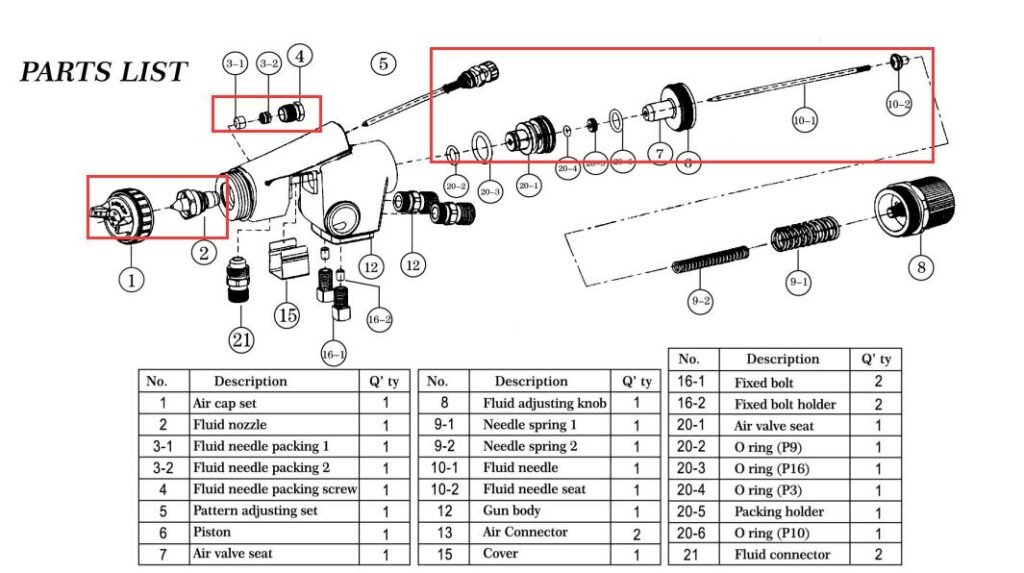

Maintains- Spare parts for the WA series

Due to industrial coatings’ high viscosity and corrosive nature, they will easily injure the inside parts. So it would help if you add some accessories when purchasing. The most worn spare parts are nozzle, fluid needle, air cap, air valve seat, packing nut set, O-rings, etc. If only for daily use for automatic spray gun, the inside parts can be worked well about 3-4 months, but if the frequency, and with high-viscosity paints, It life-span is short down accordingly. In addition, the materials of needle and needle will undoubtedly affect the service life, stainless steel is more durable than stainless iron, and it can be used for water-based paint spraying.