Many buyers will purchase low-pressure eco-friendly spray guns for the European and American markets to meet the local environmental needs. However, conventional spray guns still occupy the market because of the low price compared to low-pressure spray guns. If the spraying performance is not strictly, usually will also choose the cheap high-pressure spray guns.

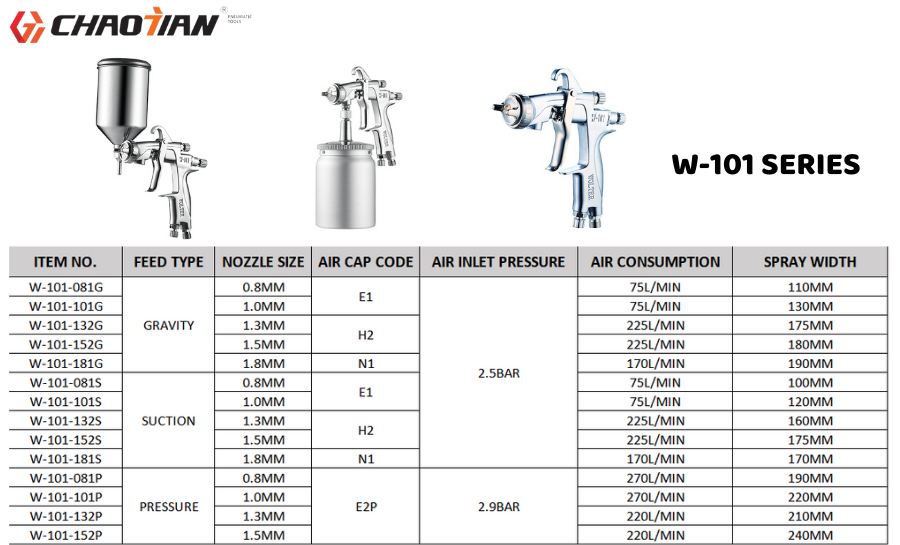

Today, I would like to introduce a paint gun classified as a conventional gun but has an eco-friendly gun’s lightweight and low-pressure characteristics. Different operational needs and usage habits required, we have three feed types that can be selected: gravity, suction, and pressure.

Product Specifications:

Product Features:

- Needle surface with specially treated for wear resistance and prolonged lifetime.

Our gun is different from others on the market. Especially in the part of nozzle & needle, we use a particular treatment method with the needle so that the surface is coated with a specific layer of chemical material. We call it a “gold needle,” which doubles the life of the whole gun!

- Patented needle-valve integrated structure

Unlike conventional spray guns with a three-stage structure, the W-101 has an integrated needle and valve structure that reduces the gun’s weight and improves maneuverability.

- Variety of atomization sets to meet different needs.

Currently, there are 0.8mm, 1.0mm, 1.3mm, 1.5mm, 1.8mm optional nozzle sizes, with 1.3mm and 1.5mm tips being the most commonly used, suitable for automotive spraying, industrial spraying, wood spraying, etc.

The regular maintenance of the spray gun is also the key to extending the life. We summarize a few maintenance and cleaning points to keep in mind.

- Air cap: whether the whole gun or spare parts should not be immersed in diluent for a long time after the work is completed, promptly clean the surface and internal with a cleaning brush, small atomizing holes need to be cleaned with special cleaning tools to avoid damage to the corner hole, causing permanent, irreparable damage.

- Needle& nozzle: disassembly requires a special wrench; ordinary wrenches will deform the taper of the edge of the nozzle, resulting in the primary and secondary airflow crosstalk, air leakage other phenomena. When removing, you need to hold the trigger tightly to avoid damage to the inner needle. After finishing the removal, observe whether dry paint is sticking to the surface. If so, use a brush to clean up before pulling out the to reduce the damage to the needle plug forced tight. When cleaning, you need to be careful not to touch the surface of the needle and nozzle with complex objects or cause the needle body to bend, affecting the atomization effect.

- Needle plug forcing group: consists of 3 layers, plastic jacket on the surface and gaskets on both sides inside. Anti-corrosion and wear-resisting, and good fluidity. With the back end of the screw with the effective prevention of paint leakage. If wear and aging, it is also easier to replace, loosen the screw at the back end, and pull out the needle if there is no paint sticking inside

We use PTFE instead of O ring or pp for sealing in adjustment sets. Which is wear-resistant and anti-corrosion, so except for replacing the needle, nozzle, air cap, and needle plug tightening, other parts do not need maintenance as long as they are not artificially damaged.