Many consumers may be confused as to why the spray guns look the same but different. For example, some colorful series of spray guns use the same model but collaborate with various artists to release some commemorative models for the collection. Each brand is constantly upgrading the 2.0 versions of the spray guns to improve the quality by optimizing some details.

As a practical tool, the spray gun needs to be constantly tested by the market and consumers, from the design of a new product to a stable finished product. Especially pay more attention to shape, that more ergonomics and comfort. Meanwhile, upgrading accessories and spray performance are constantly improving the quality of spray guns.

As a professional factory of spray guns with independent research and development capabilities, we are developing new products to meet the needs of our customers and the market. Here is a comparison of our newest NFC and the premium EFC automotive spray guns.

The NFC series spray guns are an upgrade to the EFC, so there are similarities and differences.

Similarities:

- Same precise craftsmanship& quality of nozzle, needle, and air cap

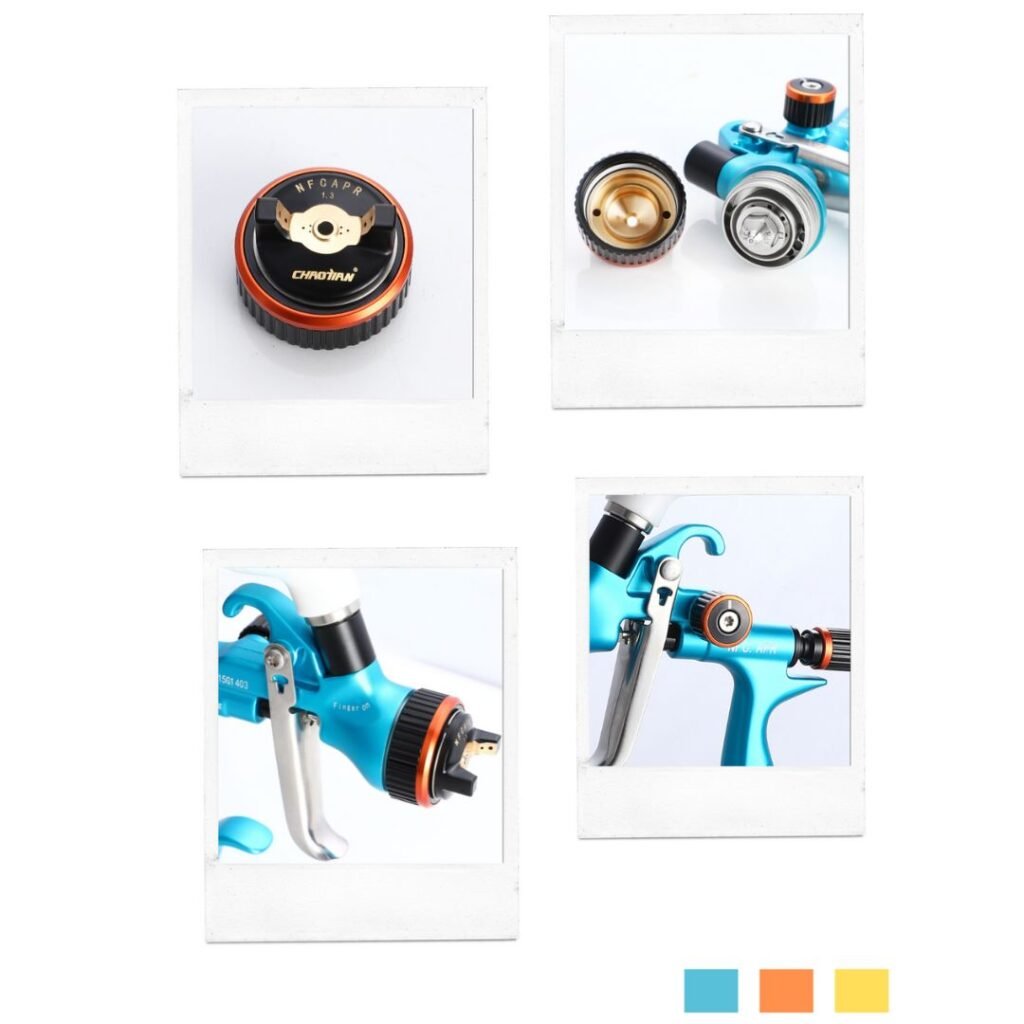

The core of a high-end spray gun is the atomization set, i.e., needle, nozzle, and air cap. The NFC and EFC are produced under international standards, with low pressure and high transfer efficiency, in conformity with the VOCs requirements. Also, there are three optional nozzle sizes and atomization technologies to choose from, 0.8mm/1.0mm/1.3mm. And HVLP/APR/LVLP types.

- Same high-grade raw materials made

The gun’s bodies are made of forged aluminum, and the fluid channel and nozzle are made of high-grade stainless steel with a brass air cap. POM plastic paint cup with good corrosion and drop resistance.

- Same patent structure of air valve-needle integrated

Patented air valve-needle integrated structure, improving excellent operability and good handling.

Differences:

- More ergonomic with the gun body

The gun’s appearance has been substantially adjusted to make it more comfortable to hold in hand, and the addition of a figure on position makes it easier to control. The gun’s overall weight is 12G less than that of the EFC.

- More durable for wear spare part

The new structure of the packing nut is a change to automatically repair the worn gasket, reducing maintenance costs and time while increasing the gun’s seal and durability.

- Quicker to adjust the volume.

The pitch on the needle adjustment set has been changed from 4.5 turns to 3 turns to open the paint channel fully—accurate and fast adjustment of paint dosage.

Innovation has always been the driving force behind the development of the company. The research and production of high-quality spray guns have enabled us to win more recognition and praise from our customers.